YOUR IDEA IS JUST A STORY UNTIL IT BECOMES A REALITY AT GLORY

GENERAL & ENGINEERING PLASTICS

With our facilities and our experienced staff we can machine, fabricate and weld a wide range of our stock materials to your exact specifications. Our talented team can work with your rough sketches, concepts and measurements to provide a finished product that we are confident you will be delighted with. Alternatively, we are able to provide our stock materials in rod, tube or sheet form.

ACRYLIC / PERSPEX

Acrylic sheet is a strong, lightweight, glass-like plastic with excellent outdoor weatherability and optical clarity. Clear acrylic sheets are 17 times stronger than glass, at half the weight. Clear acrylic sheets are a safer option as there is less chance of breakage. The appearance is similar to glass but has greater flexibility. It can be bonded with acrylic adhesives to provide a very strong clear joint. Because it weighs a lot less than glass it is much easier and safer for the DIY person to install.

ACETALS / DELRIN

Acetal's great machinability together with its dimensional stability, mechanical strength, zero moisture absorption and good load-bearing properties, make it ideal for close-tolerance parts. Acetal properties:

- High hardness and stiffness

- Excellent creep resistance

- Dimensional stability

- Excellent dielectrical properties

- Low co-efficient of friction

NYLON

Nylon rods, sheets and tubes are tough and durable. It is general purpose engineering material with special grades for specialty applications. Typical application conditions are medium speed and temperature in a rugged, abrasive, impact and high load environment.

Nylon properties:

- Excellent bearing properties

- High impact strength and toughness

- Low power factor requirements

- High wear resistance

- Very good sliding properties

PVC

PVC is a weldable plastic, ideally suited to industrial applications where chemical resistance and rigidity are a requirement. The properties of PVC give the material high rigidity and strength compared to other plastics and also allow it to be formable and machinable.

PVC Properties:

- Excellent electrical insulating properties

- Very high chemical resistance

- Thermoformable

- Moderate impact resistance and service temperature

- Very good moisture resistance

- Good dimensional stability

- Bondable Self extinguishing

PTFE (TEFLON)

PTFE is resistant to practically every chemical known to science and has best sliding properties of all typical Engineering Plastics with an added bonus that virtually nothing will stick to it. It will operate under temperatures continuously at 260 Degrees Centigrade and is unaffected by sunlight also it has excellent insulating / dielectric properties. Fillers can be added to enhance the mechanical strength and abrasion resistance.

PTFE Properties:

- Excellent chemical resistance

- Lowest co-efficient of friction

- Highest operating temperature and stability

- Physiologically inert

- Excellent electrical properties

POLYPROPYLENE

The non-polar structure of polypropylene sheet and Rod gives it a very high molecular mass. This makes PP sheet and rod highly resistant to chemicals and to aqueous solutions of salts, acids and alkalis. Polypropylene homopolymers have a high level of stiffness and toughness at room temperature. This together with their capacity to repel water makes them a good choice for mechanical and structural applications.

Polypropylene sheet properties ensure that this material is a hard, stiff, easily workable material with excellent toughness and is also available in polypropylene rod, tube and polypropylene weld rod. It is an easily weldable thermoplastic, which makes it ideal for tanks, fittings and vessels for the mineral processing, mining and galvanising industries.

- Polypropylene Properties:

- Very high chemical resistance

- Excellent impact resistance

- Higher scratch resistance than HDPE

- Thermoformable

- Excellent moisture resistance

- Food grade

UHMWPE / HMWPE

UHMWPE Polyethylene Ultra High Molecular Weight Polyethylene (UHMWPE) sheet and rod products are manufactured from the semi-crystalline polyethylene (PE) family. UHMWPE Sheet has a minimal molecular weight of 9 million, which has a positive impact on material performance in an abrasive environment. UHMWPE sheet is available in various grades of material depending on the application requirements.

UHMWPE Polyethylene properties:

- Very lightweight

- Extremely tough

- Chemically resistant

- Excellent wear resistance

POLYETHYLENES / HDPE

HDPE Polyethylene High Density Polyethylene (HDPE) is manufactured from the semicrystalline polyethylene (PE) family. HDPE is available in various grades depending on the application requirements.

HDPE Polyethylene properties:

- Very low co-efficient of friction

- Very high surface release properties

- High chemical resistance

- Excellent impact resistance

- Very good damping properties

- Weldable plastic

- Excellent abrasion resistance

- Self Lubricating

- Does not absorb water

- Very Lightweight at 0.93 specific gravity

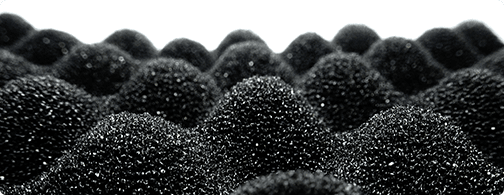

POLYURETHANE

Polyurethane Elastomers are extremely versatile materials and this has been the key to their widespread applications. This flexible engineering material is available in Polyurethane Sheet, Rod and Custom Cast Products. Polyurethane has a unique design and construction combining many of the advantages of rigid plastics, metals and ceramics with the extensibility of rubber. This material is utilized in a wide variety of industries because of the advantages of the repeatable moulding processes that deliver a quality tough and durable product.

POLYCARBONATE / LEXAN

Polycarbonate sheets, rods tubes are a premium quality, 'see-through' polycarbonate material typically used in the fabrication of guarding in safety guarding, sight glass and high impact applications. Polycarbonate is easy to handle, easily fabricated and formed, and easy to machine into parts or panels.

Polycarbonate sheet is unique for its impact resistance and its shock-load resistance. It is literally sledgehammer proof. Polycarbonate sheet is clearly the right choice for glazing where there is potential for glass breakage. These applications include schools, public buildings, transportation centres and in areas where high traffic and vandalism is prevalent. It is an excellent product for safety and security applications. in addition to being lightweight with excellent impact resistance.

Polycarbonate properties:

- Excellent impact resistance (250 times stronger than standard glass)

- Very good optical properties

- Ability to be cold formed in thinner gauges

- Moderate chemical resistance

- Self extinguishing Excellent acoustic properties UV resistant

ENGINEERING TOOL SUPPLIES

Since 1989 we have been supplying tooling to small and large engineering shops in the Hunter Valley and New South Wales north coast. With our extensive experience, we can offer the right tooling for your machining application. Because we run our own engineering machining facility at our Thornton premises, we can assess the tools that work best in the industry.

As part of the UTG Group we import our own range of tooling and also can supply from the extensive range of well known brands such as:

At GLORY-ETP we are able to draw on almost 30 years of experience and knowledge to assist you in making the right decision for your machining needs. That is why so many businesses across our region depend on us for technical advice and quick friendly service. Call us today to find out more on how we can help you.

ABOUT

GLORY-ETP offers a wide selection of stock plastics and tooling. From design and manufacture of plastic projects from concept to the machining and assembly of many industry standard engineering products, we always endeavour to provide the right solutions to turn your ideas into reality.

Glory ETP